Understanding the Role of Rapid Prototype Suppliers in Modern Manufacturing

In the fast-paced world of manufacturing, rapid prototype suppliers play an essential role in transforming concepts into tangible products. These suppliers utilize advanced technologies to create prototypes quickly and efficiently, enabling businesses to test, refine, and prepare for production without the extensive time and cost associated with traditional manufacturing methods. In this article, we will explore the intricacies of rapid prototyping, the benefits offered by suppliers in this niche, and how businesses can select the right partner to enhance their product development processes.

What is Rapid Prototyping?

Rapid prototyping is a technology-driven process that allows designers and engineers to create physical models of their products in a short amount of time. This approach is widely embraced across various industries, including automotive, aerospace, consumer products, and medical devices. Unlike traditional prototyping methods, which can be labor-intensive and time-consuming, rapid prototyping leverages digital modeling, computer-aided design (CAD), and additive manufacturing techniques to produce prototypes swiftly and accurately.

Key Benefits of Rapid Prototyping

- Speed: Rapid prototyping significantly reduces the timeline from concept to prototype. Suppliers can often deliver models within days, allowing businesses to validate ideas quickly.

- Cost-Effectiveness: By minimizing the resources required for production, rapid prototyping helps lower overall costs. Fewer materials are wasted, and iteration cycles are shortened.

- Enhanced Collaboration: Prototypes provide a tangible representation of ideas, facilitating clearer communication among team members and stakeholders, ensuring everyone shares a common vision.

- Informed Decision-Making: With rapid prototypes in hand, businesses can conduct tests and gather feedback, allowing them to make data-driven decisions about design modifications before mass production.

- Flexibility: Rapid prototyping techniques can adapt to various materials and designs, making it suitable for a wide range of products and industries.

The Role of Rapid Prototype Suppliers

While the concept of rapid prototyping is straightforward, the execution often depends heavily on the capabilities and expertise of rapid prototype suppliers. These suppliers provide specialized services that include:

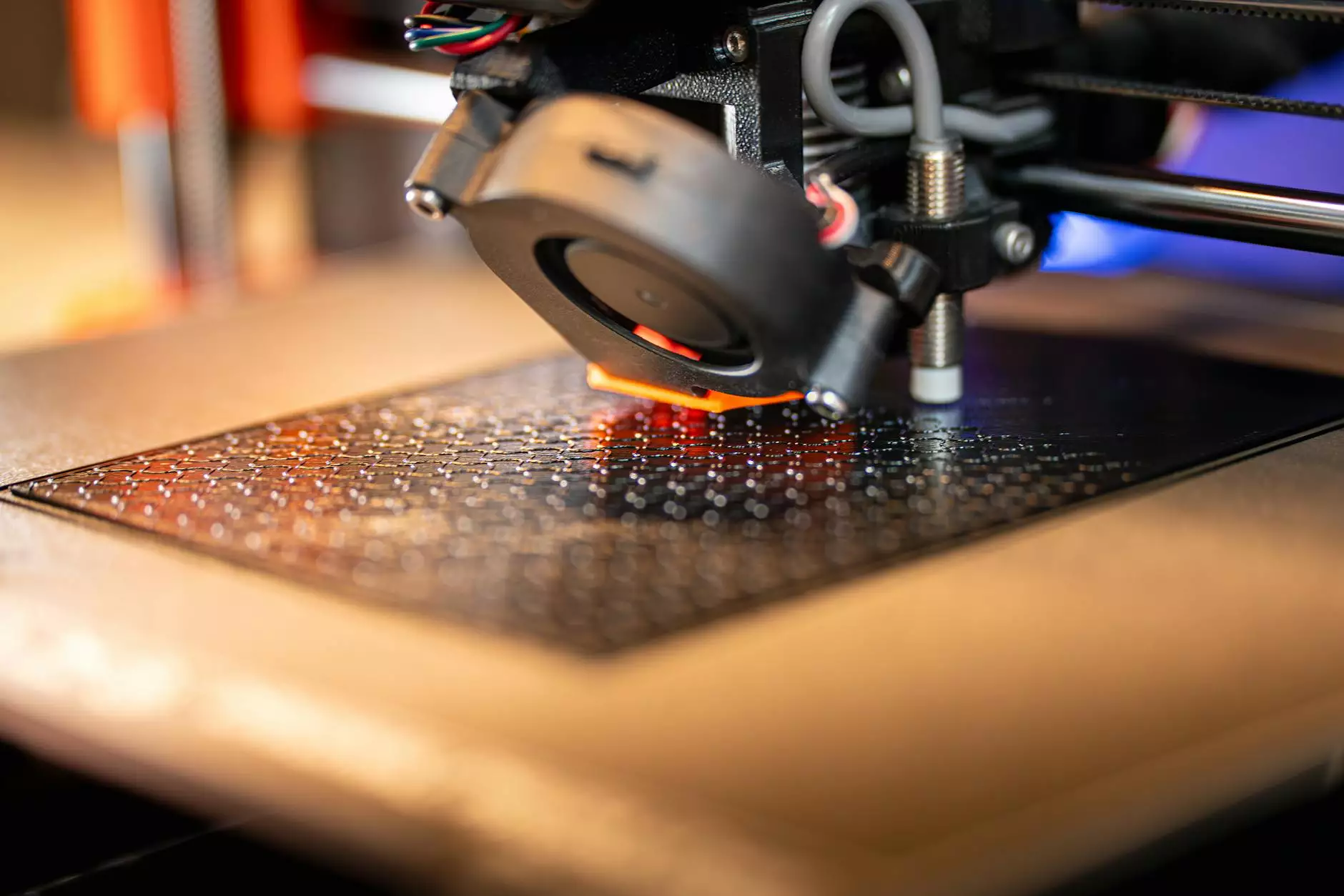

1. Additive Manufacturing (3D Printing)

One of the most common rapid prototyping techniques is additive manufacturing. This method involves layering materials to build a product from the ground up. Suppliers who specialize in 3D printing can produce intricate designs that may be impossible or too expensive with conventional methods. Here are some types of 3D printing technologies used by suppliers:

- Fused Deposition Modeling (FDM): Ideal for producing durable prototypes using thermoplastics.

- Stereolithography (SLA): Utilizes UV light to cure liquid resin, producing high-precision prototypes with excellent surface finishes.

- Selective Laser Sintering (SLS): A process that uses laser technology to sinter powdered materials, resulting in complex geometries and robust prototypes.

2. CNC Machining

Computer Numerical Control (CNC) machining is another method used by rapid prototype suppliers. This subtractive manufacturing process involves removing material from a solid block to create the desired shape. CNC machining is particularly useful for creating prototypes from metals and hardwoods, providing a level of precision that is often required for functional testing.

3. Injection Molding

For projects that demand high-volume production, some rapid prototype suppliers also offer quick turn-around injection molding services. This allows businesses to produce small batch runs of parts that can be tested in real-world scenarios. While traditional injection molding can be expensive due to the cost of tooling, rapid techniques can offer a more cost-effective solution.

Selecting the Right Rapid Prototype Supplier

Choosing the right rapid prototype supplier can significantly affect the success of your product development process. Here are several key factors to consider:

1. Technology and Capabilities

Evaluate the technologies and methods offered by potential suppliers. Ensure they have the necessary equipment and expertise in the techniques best suited for your project, whether it's 3D printing, CNC machining, or injection molding.

2. Experience and Portfolio

Look for suppliers with a proven track record and an extensive portfolio across different industries. Experience can often translate to better understanding your specific needs and overcoming potential challenges.

3. Quality Assurance

Quality should be a top priority. A reputable rapid prototype supplier will have stringent quality control measures in place. Inquire about their testing and quality assurance processes to ensure your prototypes meet industry standards.

4. Communication and Collaboration

Effective communication is critical in product development. Choose a supplier who emphasizes transparency and collaboration, as this will help streamline the design and prototyping process.

5. Turnaround Time and Scalability

Understand the supplier's turnaround times and their ability to scale production if necessary. As your project moves from prototype to production, you want a partner who can adapt to your evolving needs.

Future Trends in Rapid Prototyping

The rapid prototyping industry is continuously evolving, driven by advancements in technology and materials. Here are some emerging trends to watch:

1. Advanced Materials

The development of new materials for 3D printing and other prototyping processes is rapidly expanding. We're seeing the introduction of composite materials, bioplastics, and even metals that enhance the functionality and performance of prototypes.

2. Integration of AI and Machine Learning

With the integration of artificial intelligence and machine learning in design, suppliers can now optimize the prototyping process further. These technologies can analyze designs for manufacturability, suggest improvements, and even predict issues before they arise.

3. Increased Use of Cloud Technologies

Cloud-based platforms are enabling more collaborative design processes. Engineers and designers can work on prototypes together, no matter their physical location, leading to increased innovations and efficient workflows.

4. Sustainability in Prototyping

The push for sustainability has also reached rapid prototyping. Suppliers are exploring eco-friendly materials and methods to minimize waste, aligning with global trends toward more sustainable manufacturing practices.

Conclusion

In conclusion, rapid prototype suppliers are integral to modern manufacturing, providing essential services that enable faster, more cost-effective product development. By understanding the various methods and selecting the right partners, businesses can leverage rapid prototyping to enhance collaboration, improve efficiency, and ultimately bring better products to market. As technology continues to advance, keeping an eye on emerging trends will ensure that you stay at the forefront of innovation in your industry.

If you are looking for a reliable partner in your rapid prototyping journey, look no further than DeepMould.net. With a commitment to quality, cutting-edge technology, and a customer-centric approach, we are well-equipped to help you develop and refine your product ideas successfully.